aluminum extrusion machine factory

- ruijia

- jiangsu

- 20 days

- 100sets/month

We are a professional supplier of metal extrusion equipment,We can make a whole program for you, only need you to provide the following information:

1. Drawing.

2. Product material requirements.

3. Product Usage.

4. output.

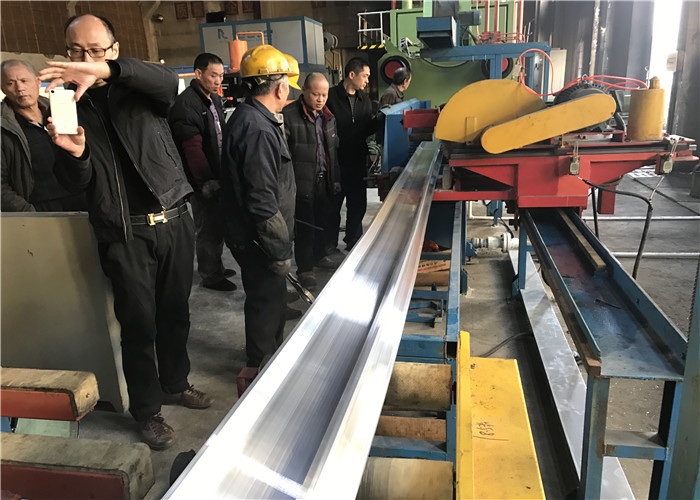

The extruder is suitable for various deformable metal extrusions, especially for metal extrusion of copper, aluminum, lead, zinc, silver, etc.

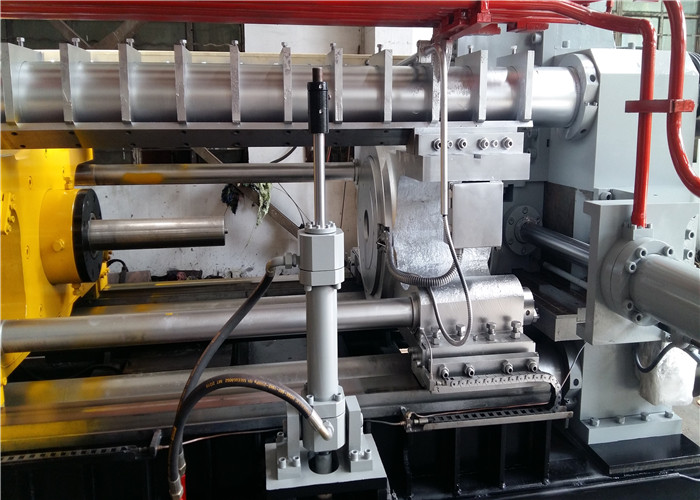

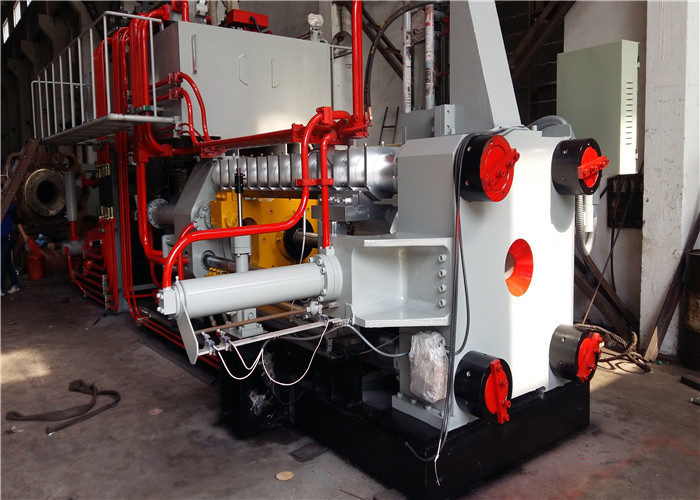

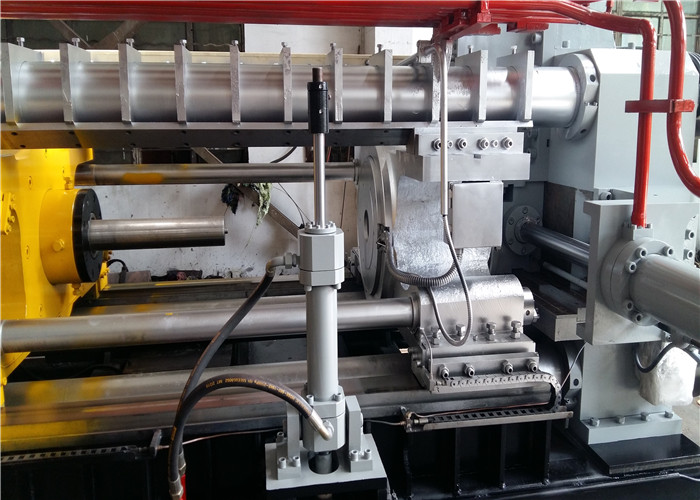

The main parts are the master cylinder assembly, the front beam assembly, the movable beam that drives the squeeze rod, the extrusion cylinder (front and rear), the spindle feeder, the die changer, the main shear with automatic pressure reduction, and the hydraulic device.Using PLC (brand optional), hydraulic manifold (cartridge valve), oil pump motor group (speed control oil pump, servo) to achieve stepless speed regulation (constant speed), manual automatic switching and other functions。

Our extruder equipment is easy to operate, highly automated, and energy efficient.

Extruder operation:

1. extrusion cycle:

The extrusion control allows the use of fully automatic repeating cycles or semi-continuous automatic cycles. The extruder can provide the following operating cycles:

1) Loop based on control mode selection:

A. manual.

B. a cycle automatically (starting from the extrusion tube)

2) Extrusion speed (optional constant speed):

The extrusion speed can be adjusted from zero stepless speed to the maximum speed value by means of a preset device on the operating screen. In the automatic cycle, the extrusion speed can be programmed to determine the filling speed, extrusion speed and reduction ratio.

3) Temperature control of the extrusion barrel:

4) The heater in the extrusion cylinder is equipped with a thermocouple. According to the signal of the thermocouple, electric energy is input into the heating, and the temperature is controlled by a comprehensive device for displaying each temperature.

5) Security control:

The control of the extruder has interlocks to prevent damage to the equipment due to mishandling. An emergency stop button is provided on the operation panel.

2. Technical parameters of the electrical part:

1) Input capacity and voltage

A) Input voltage: AC 380V 3 phase 50HZ

B) Control loop: AC 220V 1 phase 50HZ

2) Grounding.

Neutral----------- firmly grounded

3) Power supply system, 380V AC, 3-phase, 50HZ, capacity (depending on the size of the device)