Aluminum Profile Production Line

- ruijia

- jiangsu

- 20 days

- 500sets/month

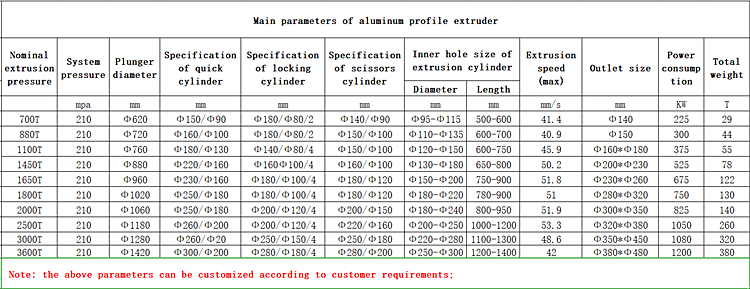

Extrusion machine product introduction:

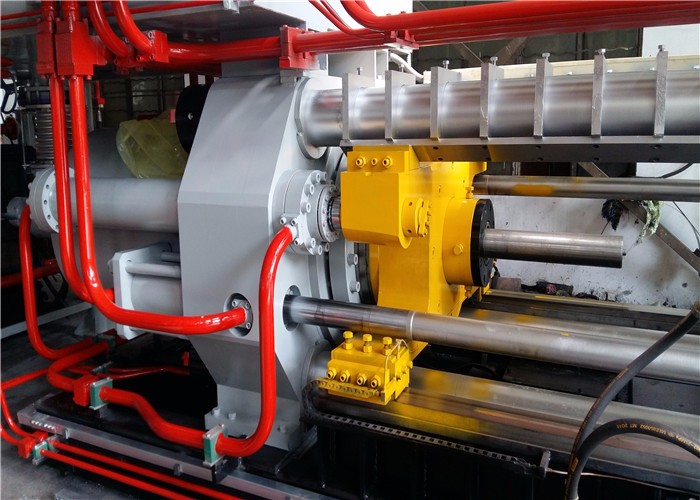

The main cylinder assembly and front beam assembly of the extruder are connected by four Φ170mm tension columns. The movable beam, the squeeze cylinder, the spindle feeder, the die changing device, the main shear with automatic pressure reduction, and the hydraulic device are driven by the squeeze rod. The extruder is supported by a base of welded steel construction.

We are a professional supplier of metal extrusion equipment,We can make a whole program for you, only need you to provide the following information:

1. Drawing.

2. Product material requirements.

3. Product Usage.

4. output.

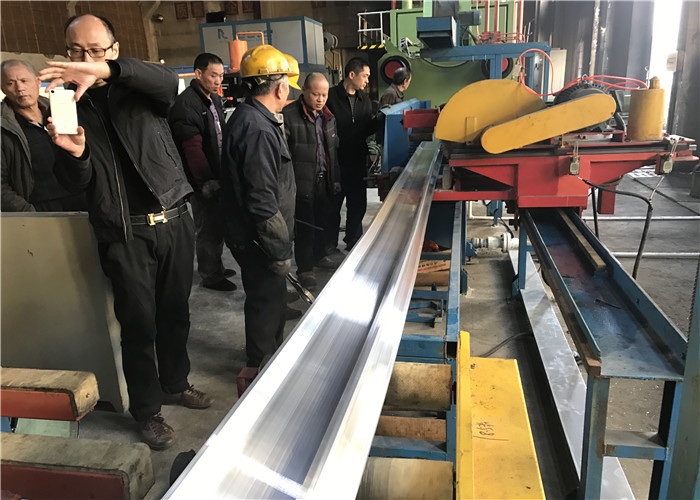

The extruder is suitable for various deformable metal extrusions, especially for metal extrusion of copper, aluminum, lead, zinc, silver, etc.

The main parts are the master cylinder assembly, the front beam assembly, the movable beam that drives the squeeze rod, the extrusion cylinder (front and rear), the spindle feeder, the die changer, the main shear with automatic pressure reduction, and the hydraulic device.Using PLC (brand optional), hydraulic manifold (cartridge valve), oil pump motor group (speed control oil pump, servo) to achieve stepless speed regulation (constant speed), manual automatic switching and other functions.

Our extruder equipment is easy to operate, highly automated, and energy efficient.

Technical parameters of the electrical part:

1) Input capacity and voltage

A) Input voltage: AC 380V 3 phase 50HZ

B) Control loop: AC 220V 1 phase 50HZ

2) Grounding.

Neutral----------- firmly grounded

3) Power supply system, 380V AC, 3-phase, 50HZ, capacity (depending on the size of the device)