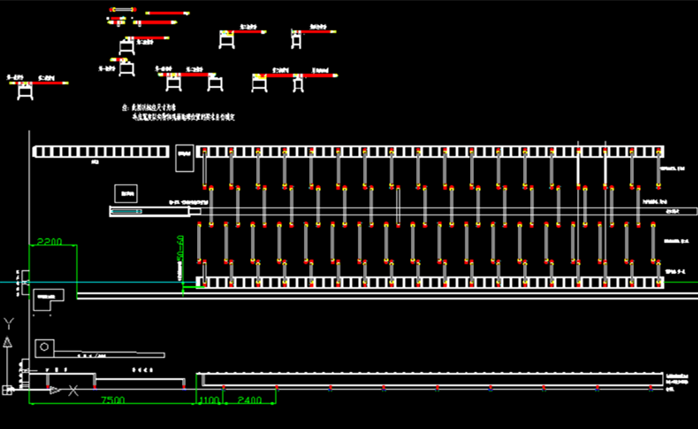

Parallel Type Cooling Bed

- ruijia

- jiangsu

- 20 days

- 100sets/month

Product advantages:

The cooling bed is mainly made of independent belt-changing (translating) conveying aluminum profiles,Control by PLC.

When replacing the felt strip, it is not necessary to remove the entire long shaft like a traditional belt type cold bed. As long as the screw is loosened, the felt strip can be removed, has the advantages of simple structure and convenient operation.

The high-temperature felt belt is used to convey the aluminum profile, which effectively prevents secondary bumps and deformations during the conveying process ,reduces the waste. At the same time, it provides a clean and tidy table for the profile,ensure the appearance quality of the profile.Therefore it is applicable for the enterprises to manufacture the section material with large, middle or small specification.

It is especially suitable for the requirements of rapid extrusion of extruders, improving production efficiency and product quality and yield.

The system adopts PLC control, the sliding lifting platform, the feeding platform and the cooling table are all equipped with the extruder and the tractor to operate periodically. The straightening table is manually operated to telescope and drive, the storage platform is manually operated, and the sawing table is driven. The finished saw sawing material, the fixed length table and the inspection table transmission all adopt the manual one-button operation of the periodic action, and all the one-button operation periodic actions can be converted into the manual mode step-by-step action.

The cold bed conveyor system is equipped with a complete protective program to avoid the occurrence of dry collisions; the hydraulic drive action such as sliding the table saw table lifting and the finished saw blade feeding can be manually adjusted.

We are a professional supplier of aluminum profile equipment,We can make a whole program for you,only need you to provide the following information:

1. Drawing.

2. Product material requirements.

3. Product Usage.

4. output.